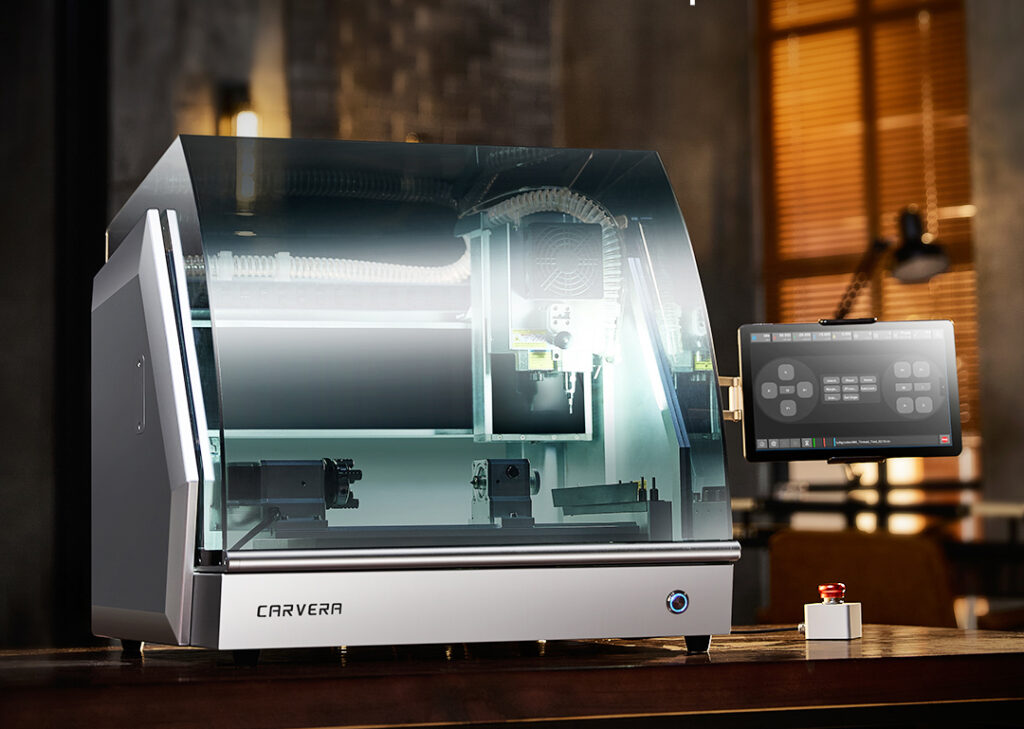

Precision automation, versatility with several materials and intelligent workflows. Carvera and Carvera Air change the way creators at home doer machine.

For decades, the CNC systems (Computer Numerical Control) have been captured behind industrial walls and requires special training, bulky machines and five imaging investments. The Air from MACERA from Carvera and Carvera define this standard with compact, closed machines that integrate extended automation, 4 -xen functions, hybrid tool support and intelligent design into an accessible desktop format.

The Carvera series was built for engineers, product developers and serious makers and offers a platform that combines industrial performance with intuitive control. It opens the door to complex multi tool operations, real -time calibration and multi -material production without friction or overhead traditional CNC systems.

Automated precision with technical simplicity

The flagship Carvera model is equipped with an integrated automatic tool (ATC), so that seamless tool transitions can be equipped in a single job file. Combined with automatic testing and leveling in real time, the machine decides manual zero point and material surfaces. This enables continuous operations over several tool paths with precision up to micrometers.

The Carvera Air, an optimized sibling model, acts the ATC against a new mechanical quick change design. With a single lever system, users can replace bits in seconds without a new calibration. This mechanical innovation reduces the loss of time between the operating processes and keeps the innovation company of the tools even with high torque passes.

Both models use servo -driven control systems for closed loops that offer constant positional feedback. These systems correctly for the drift or the mechanical variance in real time to ensure consistent cutting forces, exact tool paths and reduced wear in long workplaces and thick materials.

Multi -material -ability and structural integrity

Spindle speeds of more than 18,000 rpm, coupled with a reinforced chassis and a vibration damping, enable the Carvera series to manage an expansive area of substrates such as aluminum, brass, PCB, acrylic, hardwood, carbon fiber sheets and composites. The result is a system that supports everything, from prototyping from high fidelity to the production of parts.

Each unit is attached to improve not only the safety of the users, but also environmental control. The suppression of the dust, acoustic insulation and thermal stability are constructed directly into the machine body. This enables continuous use in home improvement or academic laboratories without disturbing the surrounding space.

Extensive functionality with the fourth axis and hybrid tools

Advanced users can unlock 360 -degree processing with an optional Rotary module of the fourth axis. This enables the real indicated and continuous rotation for cylindrical or multi -face geometries and expands the possibilities for mechanical prototypes, modeling of aerospace components and jewelry foci.

Adding an integrated laser engraving head transforms the Carvera into a hybrid manufacturing platform. Users can apply raster or vector-based surface treatments to wood, leather, plastic or anodized metals in the same software environment.

Integrated CAM software and complete workflow control

The proprietary cam suite from MARERA brings the entire process to a single interface. It supports 2D and 3D tool paths, rotation processing, laser engraving and multi -surgery sequencing. The software is compatible with Windows, MacOS and mobile platforms and includes a live preview, the detection of smart errors and the toolpath simulation to ensure a reliable execution before the material is touched.

For professional users, the CAM environment includes support for custom mail processors, adaptive clearing strategies and real -time spindle and feed rate adjustments. It is also integrated directly into the popular design software to create a smooth transition from CAD for cutting.

Built for a new class of independent manufacturers

The air in Carvera and Carvera are not entry -level machines. These are tools for serious manufacturers, engineers and experts for digital production, which repeatable in a small footprint, require electricity and modularity. These machines have already been used in more than 50 countries and serve as core manufacturing instruments in design studios, robotics laboratories, hardware startups and university development departments.

Carvera Air's crowdfunding campaign, which brought in almost $ 3 million, reflected an emerging appetite of makers on serious CNC solutions, for which no industrial overhead is required. Macera provided this with a system that is as intelligent as it is robust.

According to founder Josh Zhang, the mission is to eliminate the barriers between concept and creation. “We don't build a hobby tools,” he says. “We build intelligent systems that enable independent creators to produce their own conditions with professional accuracy.”

A platform for innovation and digital craftsmanship

With the focus on the support of ecosystems, MARERA supports its hardware with a global user community, comprehensive documentation and technical instructions that accelerate learning and productivity. Tutorials, modular expansion kits and firmware updates are consistently published to ensure that users can scale their functions alongside their ambitions.

Regardless of whether the components of the aerospace class, prototyping housing for IoT devices, the production of visual arts or the creation of user -defined PCBs, the Carvera series receive control and precision of a professional shop on a desktop.

In a world in which microfactories and home laboratories become the new limit of product development, the Carvera machines from MAMERA not only stand out as tools, but also as platforms for real digital innovations.