“Whenever he starts his career, he will have no problem getting hired by a company – they will be happy to have him.”

SPRINGDALE, Ark. – A Don Tyson School of Innovation graduate is mastering a technical education not offered at any other high school or local post-secondary program in Northwest Arkansas.

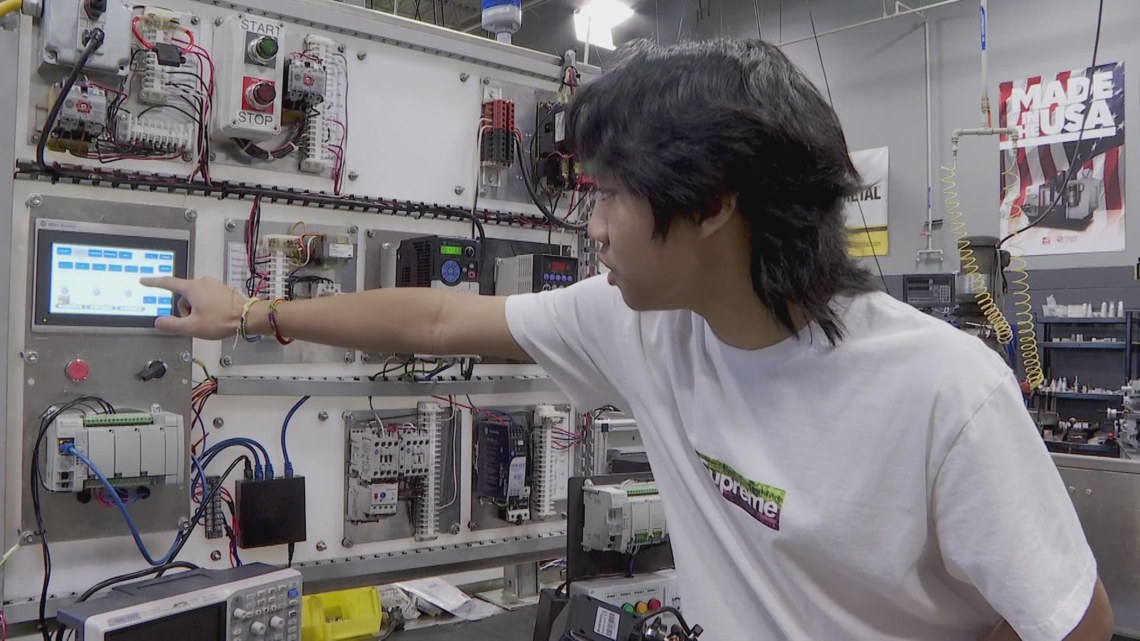

Judah Keomoungkhoun works with industry-recognized automation equipment typically used by professional technicians and builds systems that mirror large distribution center operations. He built the machine himself at school using their materials and has now completed the project after three months.

One component, an Allen-Bradley Micro870 PLC, is essentially the “brains” of the system – a small industrial computer that tells machines when to turn on and off, speed up or slow down. He programs it using Ladder Logic, a visual programming language commonly used in factories.

“Behind me I have a control panel, it's a simulator. It's all pretty much DIY, it's not a trainer that you can just buy, but it's very close to the real world,” Keomoungkhoun said.

It also operates a 7-inch HMI touchscreen, which serves as a control panel for the entire system. The PowerFlex 525 variable frequency drive controls how fast the conveyor belt motor rotates, and electric photo eyes work like the sensors on automatic doors, detecting when product passes in front of them.

“We have a PLC, we have an HMI and we have a variable speed drive and we have all kinds of relays and motor starters to make sure everything starts together,” he said.

Next to him, the conveyor belt demonstrates the functionality of a real distribution center.

“I have a motorized conveyor belt next to me that just moves back and forth, showing where the product is on the line,” Keomoungkhoun said.

Using the touchscreen, an operator can start, stop, reverse, cycle, or change speed of the conveyor belt while keeping track of where the products are on the belt.

Instructor Wesley Higginson said Keomoungkhoun programmed the system to perform tasks in large logistics centers.

“He programmed it so that it can identify a product as it goes down the conveyor belt, and it will determine whether that product needs to go to Fayetteville, Bentonville, Springdale, Rogers or wherever. And then it will document how many items go to each store so it has a tally of the total products that go down the conveyor belt,” Higginson said.

Higginson said Keomoungkhoun's skills are already comparable to those of industrial technicians.

“Judah is way above the bar and has such a head start as he begins his career. He will have no problem getting hired by a company – they will be happy to have him,” he said.

Keomoungkhoun has also added a barcode reader and RFID technology – the same tools that modern fulfillment centers use to identify and track products.

He is currently setting up a smaller training unit to teach others about automation.

“He's actually building a modular unit that can go from school to school and teach other students about automation,” Higginson said.

Local industry leaders have also recognized Keomoungkhoun's abilities.

“During our industry day, there was a large company here and Judah was here explaining what this system does. And the project manager from that company came and looked at me and said, 'This gentleman is talking to me at the same level that my automation engineers are talking to now,'” Higginson said.

For Keomoungkhoun, the process itself is satisfying.

“It's kind of relaxing putting everything together and making sure everything looks organized and nice and everything works,” he said.

He also wants people to understand how much automation impacts their daily lives.

“It's very important because people don't think about how much this impacts their lives, you know, how they get their Amazon packages, how they get their food and so on. It's very important and people don't really think about it,” he said.