Compared to the light emission diode (LED), the laser diode (LD) takes advantages without efficiency drop, high performance density and high collimation, which makes it a potential light source in the ultra-high-brightness lighting fields such as search lights, auto-clay, deep-sea lighting and aerospace lighting, the lights of aerospace lights and Aerospace lights is [[1]Present [2]Present [3]Present [4]]. So far you can integrate a blue LD with a Y3Al5O12: CE3+ (YAG) Phosphorus is regarded as a recognized method to achieve white light, for which a color converter with high heat resistance is required to endure high laser energy and huge phosphorus-converted heat [[5]Present [6]Present [7]Present [8]Present [9]]. Some inorganic converters with excellent heat resistance were developed to replace traditional phosphorus-in-silicone (PIS), including single crystal (SC) [10]Transparent ceramics (TC) [11]Phosphorus-in-glass (pig) [12]and pork film (Pigf) [13,14]. Among them, the PIGF converter has attracted dramatic attention due to the advantages of a coordinable luminescent performance, cost -effective costs and the simple preparation process [15]. Due to the low thermal conductivity (HC), conventional pigs are exposed to low laser power density (LPD) under a severe luminescent saturation, which limits the high luminous can of the laser lighting.

It was proposed that a passive thermal management of Pigf (with the heat-leading substrate) coated substrate (pigf-hcs) is coated in order to solve the above problem [16,17]. According to the difference of propagation of the emissions light [18]. The reflective pigf HCS can wear higher LPD, which benefit from sufficient reflective substrates and superior heat transmission [19]. Due to the high reflection assets, the similar heat expansion coefficients (CTE) and low costs al2O3 Ceramic material is the usual HCS that realizes the mainstream -pigf@al2O3 Converter for reflective laser lighting [[20]Present [21]Present [22]]. The Pigf@al2O3 is still confronted with the luminescent saturation under low LPD (-2) due to the limited HC of al2O3 Material and one -sided heat discharge structure. Although the simple method of al2O3 Replaced by aln with high HC increases the heat transfer of Pigf, the Pigf@aln shows a low glowing effectiveness, which comes from the low reflection capacity, and the undesirable light absorption of aln [[23]Present [24]Present [25]]. The reflection assets can be improved by adding a BN glist or Tiio2-Glass layer on the Aln surface, but this increases the interface heat resistance [[26]Present [27]Present [28]]. Since the mode of the lower heat conduction is similar to the high-performance chip, some active methods for thermal management were introduced in the Pigf@al2O3in which the Pigf@al2O3 is combined with the cool fan, the thermoelectric cooler, the microcla cooler and the steam chamber [[29]Present [30]Present [31]Present [32]Present [33]]. These active methods only improve the singles page heat department of AL2O3 Substrate and also require a complex process and high costs. It is believed that the achievement of several heat transfer channels from Pigfs is a more direct and effective method. Some double -sided thermal designs were developed for pigfs, including Sapphire@Pigf@Sapphire, al2O3-in-Glass (AIG)@Pigf@Sapphire, Sapphire@Pigf@al2O3 [[34]Present [35]Present [36]]. However, these double-sided structures are only a longitudinal cable, and their heat department is seriously influenced by the surface quality of Pigf and Substrate. It is important that the entire spatial dimensional heat transfer channels in the Pigf@al were not taken into account2O3 Converter so far. In this case, the existing thermal design hinders the achievable luminesian saturation of reflective pigf@al2O3 For laser lighting.

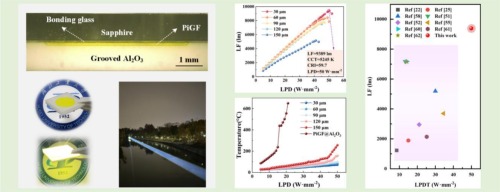

Here we designed a new architecture of the multi-channel-thermal conductive Pigf (MTC-Pigf) value with high laser performance density swell (LPDT) for laser lighting with high brightness. The MTC-Pigf converter was produced by a YAG pig sacrificed into a grooved al2O3 Substrate substrate and then stacked with a sapphire cover plate via thermal compression binding route. The MTC-Pigf converter benefits from efficient longitudinal and lateral heat channels from the MTC–2. As tabular in Table 1, the MTC-Pigf converter shows the best LPD and LF compared to the previously registered reflective pigs under passive and active thermal management modes. In order to objectively evaluate the performance of the proposed pig within the field, a summary of inorganic phosphorus converter such as phosphorus ceramics, individual crystals and pigfs is carried out (Table S1, Support information). The working temperature of the MTC-Pigf converter is only 72.5 ° C. even below an LPD of 50 W · mm.–2While that of traditional pigf@al2O3 The converter rises sharply to over 650 ° C. The MTC-Pigf converter enables an overly stable optical performance compared to the Pigf@al2O3 Converter under long -standing continuous laser.