✕

For those among them who do not yet know me, I am known as Nate The House Whisperer: I take people with human arches and/or unhealthy houses and convert them to life to comfortable and healthy places.

How do I do that? With applied physics. I use an alchemy of insulation, air sealing and the HLK to successfully deliver projects – with a final ratio of 92% and strong certificates from customers.

Since 2017 I have immersed myself in the HLK industry to discover the goal – and, if necessary, to find a way – to make a way to provide healthy and comfortable houses for consumers.

What I learned – is that the way to better houses through HLK May exist, but is very fragmented.

On the one hand, it is not sensible not to make enough demand for the HLK industry in the HLK industry. These projects are more suitable for boutique consultants like me, who have a strong understanding of the construction shell side (insulation and air sealing).

On the other hand, the collaboration with HLK contractors and their customers in the whole country taught me that a considerable part of the house area can be done with HLK alone, which really surprised me. I found the average home worse than it is.

There are very simple measures such as large media filters, upgrers more near device channels, fresh air intake channels and right -sized devices with variable speed that can be positive for customers and receive my preferred and often belonging customer comment: “I can. I don't think this is the same house. ”

But there is a problem. I consider this simple HLK system for common sense as easy to sell and install, but I constantly hesitate to refer customers to the vast majority of the contractors because the remarkably poor average residential assembly.

The improvement of the installation quality and customer results are two main boost of this column.

I come from the production where Six Sigma is a gold standard: a bad product of one million. It is difficult to meet, but feasible.

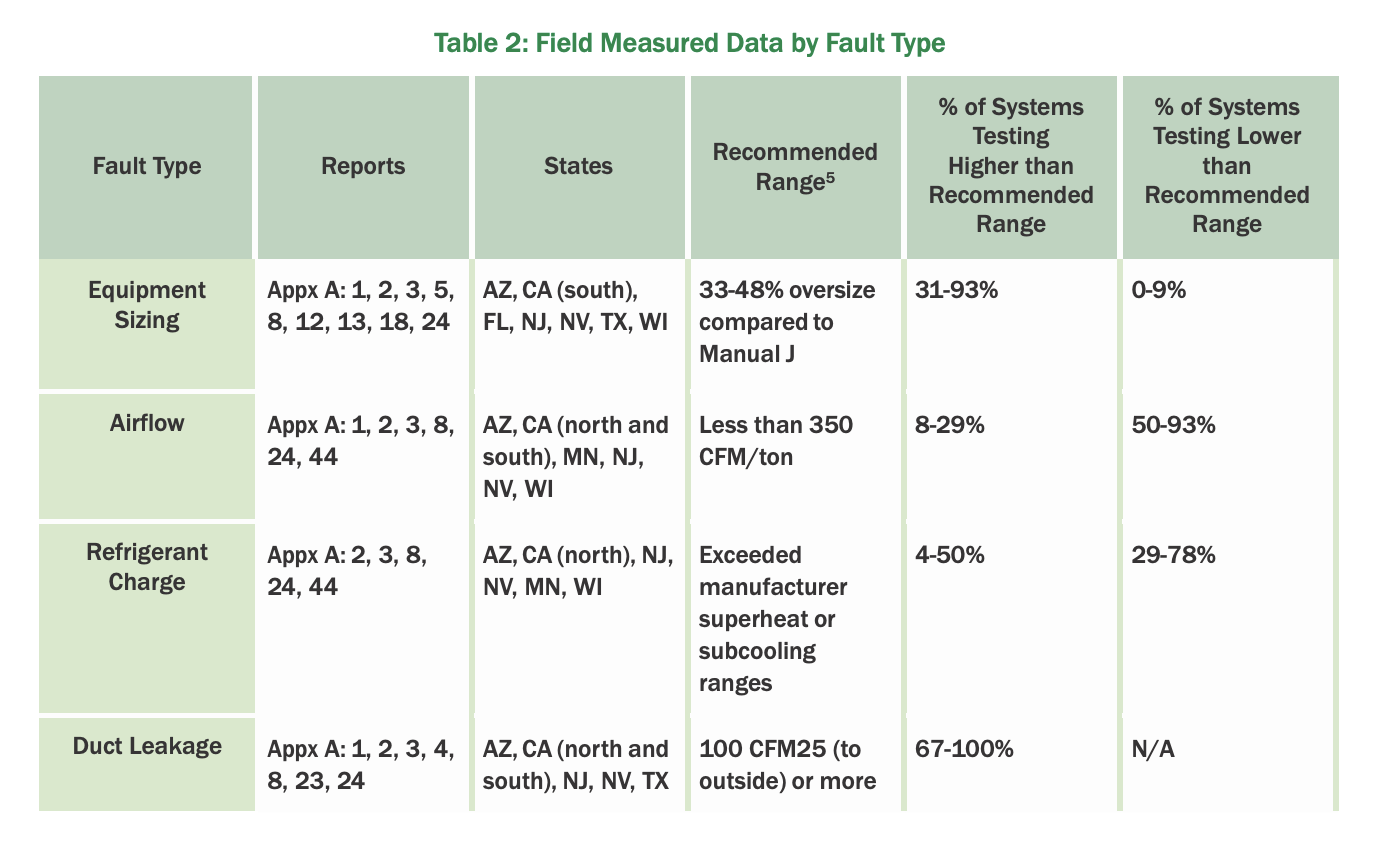

Compared to HLK installations in the residential building, they are not only bad, they are hideous. A few examples:

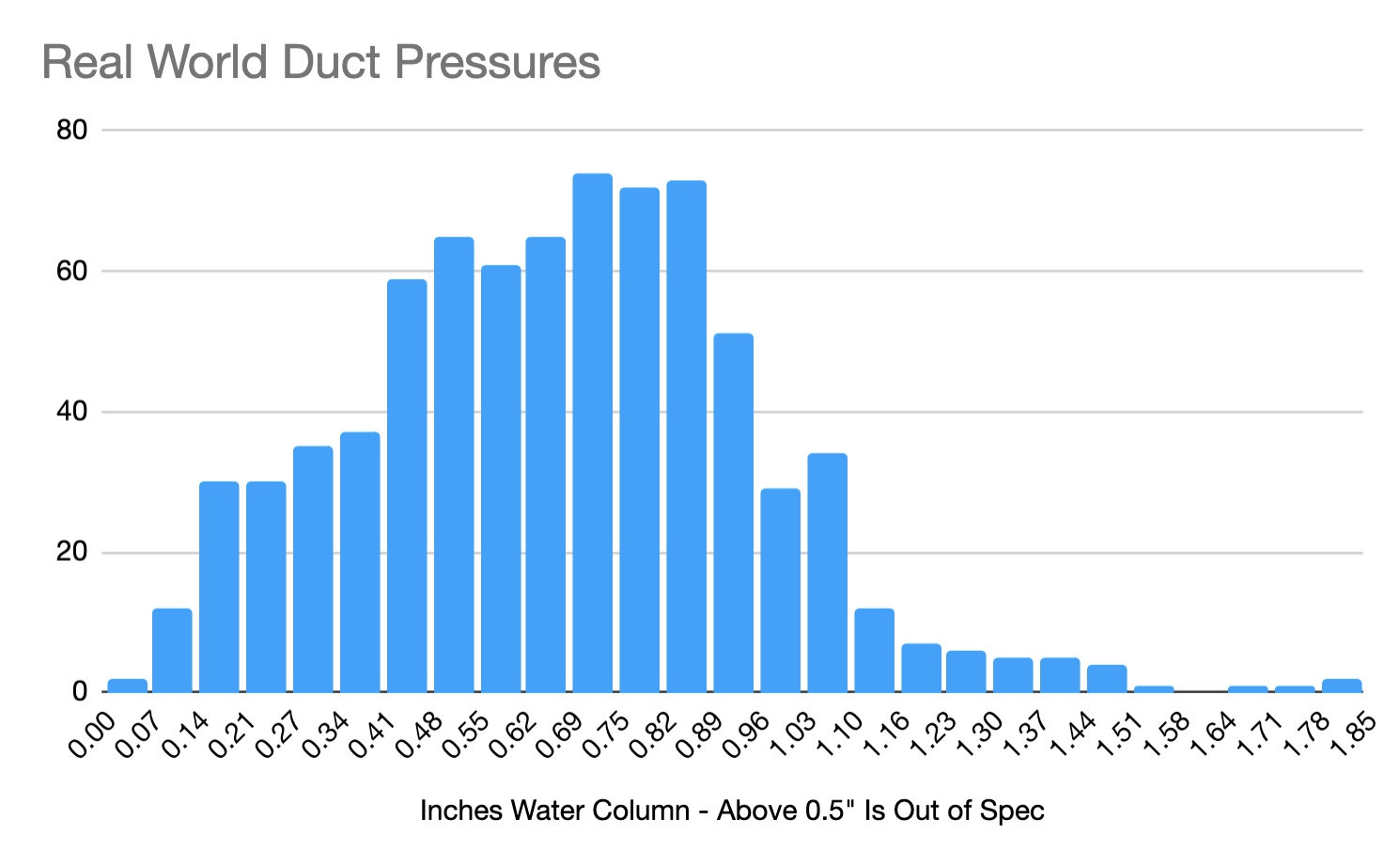

- According to Messquick data, 70% of the HLK systems in the USA are above the 0.5 -inch water column.

- 34% of the new installations have callbacks in a company of $ 50 million that I know, which implies that more problems have. The static pressure is not measured in this company.

(With the kind permission of Nate Adams)

(With the kind permission of the US Ministry)

So not only we don't just meet one of one million, we also have 9-in-10 wrong.

In the past, we were able to get away with mediocre installations, since PSC engines are very forgiving, tolerated 80% afung stoves very high temperature, and many ACs somehow survived a bad air flow without icing.

The efficiency standards have now taken robust devices and made it much more sensitive. EC engines are far more sensitive to static pressure. Even worse: switching from PSC to ECM typically leads to a TSP of 30% according to the field measurements by Jeffrey Howard, one of the best technicians I know, and now a coach at Carrier. Systems that were border are now critical.

Slow secondary heat exchangers are a consistent complaint from my service -tech friends. The efficiency of almost 100% is required with the need for better installations. These are just two examples of how systems are more sensitive to install quality today.

Private equity can also be a challenge, with a much stronger focus on short -term profits than the typical technician owner, which can lead to poorer results if it is not properly managed.

(With the kind permission of Nate Adams)

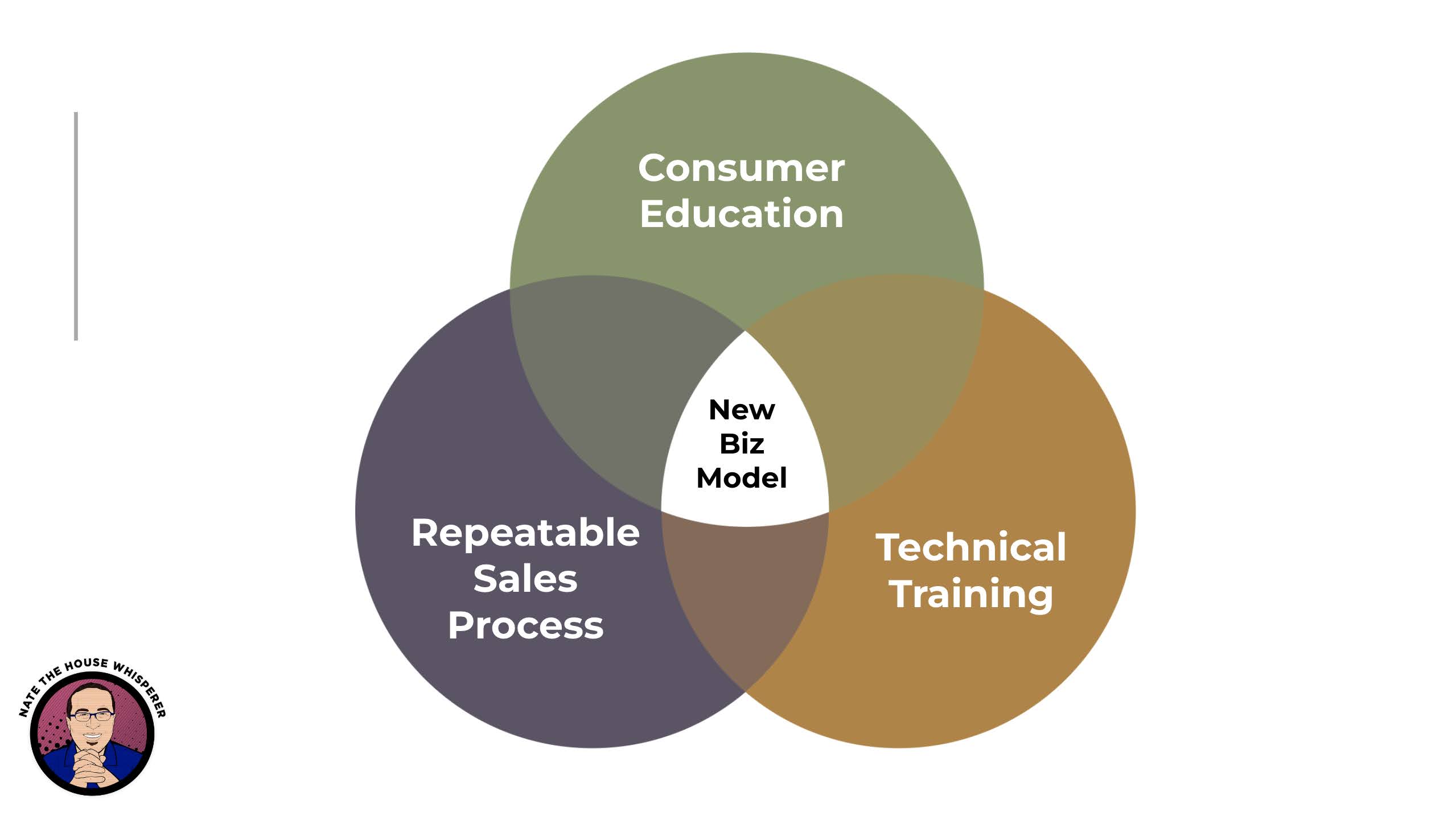

How can we master these challenges? I am firmly convinced that it is a combination of three things: solid consumer training (preferably from a trustworthy third party), a sales process that uses this training and a good technician.

These three help together to understand consumers why better installations and better devices are often needed, build up the value so that they can be sold profitably and ensure that the systems are installed correctly without stressful processes.

I have been in windmills for a decade to deliver comfortable and healthy houses, hopefully I can help on the educational page and hopefully a company can recommend a company to become much easier than today!

The next time I present a critical comparison between the automotive and living and residential assistant -HLK, hopefully a few points will also connect your customers for you and with luck.