The comparison of the percentage change in the hardness between the bleached and unbounded (control) groups for each material resulted in significant differences. In addition, both the type of material and the duration had a significant impact on reducing hardness (P

The comparison of the change in the hardness percentage between polished and unpolished samples for each material resulted in significant differences, which led to the rejection of the third null hypothesis. The filling weight has significantly influenced the material softening of the polished samples, but had an insignificant effect on the non -polished samples. Therefore, the fourth null hypothesis was partially accepted. In addition, bleaching influenced the surface roughness of some, but not all examined materials, which led to the partial acceptance of the fifth null hypothesis.

Vita Enamic, an interm-ending ceramic polymer network, will report permanently against dismantling25.26.27.28 And has shown the highest material softening of all tested materials in both polished and unpolished groups. This is contrary to the results of previous studies in which it was shown28.29 And even to increase the micro hardness after bleaching at home30.31. VE has a field -spatic ceramic structure that has shown less soft resistance than zircons -containing materials23.

RCBs showed a larger material deviation than Vita Enamic. However, a higher filler content correlated with increased material softening. For example, GN showed a larger one with a filling weight of 86%by weight than LV, BR and CS, which in the polished group a filler weight percentage of 75%by weight, 70%by weight or. 66 weight%. In addition, LV showed greater material softening than both BC and CS. This could be explained by the fact32. In addition, silanes tend to collapse into resin composite materials over time33. On the other hand, LV showed a larger material for the unpolished group than GR, which could be explained by the presence of defects and hollow rooms within the nano -meter of LV; Hence more levels of surface reduction34 Could be expected for rough or unpolished surfaces.

With regard to the effect of the polishing of the samples on the material softening resistance, all non -polished surfaces showed less resistance to softening than the polished surfaces. The unpolished group better represents the clinical conditions of the restorations. In the oral cavity, tooth restorations are exposed to moisture, temperature, acid and mechanical voltage, which can generate rough surfaces that are more susceptible to increased penetration due to bleach. This could then be an indication of Polish tooth restorations before the procedures are bleached.

The current study resulted in a positive correlation between the filler weight and material softening in the polished group, while in the unpolished group an insignificant positive correlation was observed for all tested materials. These results in contrast to previous studies in which a negative correlation between material thunderstorm and filler weight reported on various storage media35.36 and bleach37. In addition, the significant correlation between the filler weight and hardening (RR2 = 0.79) in polished surfaces was reported in an earlier study31. This discrepancy can be attributed to factors such as the filler microstructure, the homogeneity of the fillers and the degree of networking between the fillers and the Harzmatrix, all of which can influence the interaction between the restorative materials and the bleaching agent38.

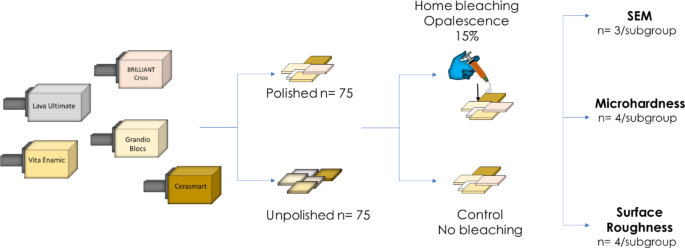

Different techniques can be used to evaluate surface roughness, e.g.32. In this study, the surface roughness using the profileometry was assessed and further analyzed with SEM.

The surface roughness of all the tested materials tested was influenced by the bleaching of home, with the exception of those of GN in the polished group, which is comparable to similar studies25.26.27.28. This can be due to the chemical interactions between the bleach and dental materials29.38which can also be influenced by the composition of the bleach and by the bleaching time and concentration20.29. Nevertheless ARA The border point for preventing the biofilm accumulation is value of 0.2 μm39. This value was exceeded for unpolished samples from VE, LV and GN. In addition, SEM images of the polished group showed that LV had a stronger cluster formation of filler particles, while GN and CS showed deposit between the filler and polymer matrix. In addition, the SEM images of the non -polished group of all tested materials tested showed less different particle edges and more rounded particles after 56 hours of bleach and one month after bleaching. It is therefore advisable to protect the restoration by polishing from bleaching agents.

The choice of including both polymer-infiltrated ceramic networks (PICN) and resin composite blocks was intended to present the entire spectrum of CAD-CAM composite materials. This ensures a broader understanding of how the bleach influences the materials with different polymer and ceramic content.

Although the impact of the homeless bleach was examined on the surface properties of various restoration materials, this study has restrictions. The effects of the bleaching of the house on the optical properties, the colorability of the CAD cam material and the biofilm formation were not evaluated. In addition, only one pick material (Vita Enamic) was used, which may not be all available hybrid materials. While in-vitro studies offer controlled diseases, clinical studies convey a more comprehensive understanding of how the bleaching of home can affect the surface properties of CAD-CAM restorations. In addition, it would be clinically relevant to mechanically test the fatigue resistance and fracture of CAD cam materials that are exposed to home bleach.